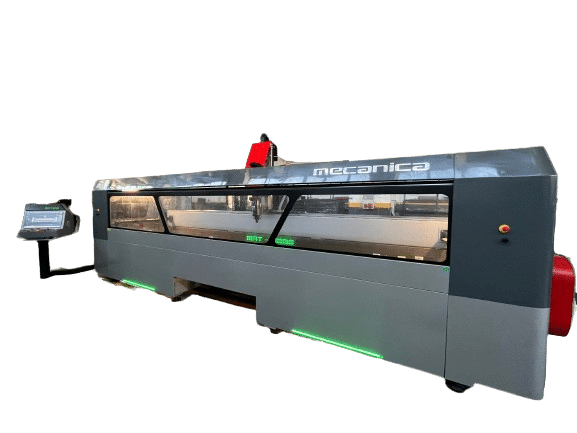

Increase your production, improve your capacity, save your money, raise your space; MAT4800/5 ORCA profile machining center is suplied with an enclosed protection cabin with an 4800 mm working lenght and also 5 axis machining capacity. Also it has special movable zero point which you can use the machine like a 2 small CNC Aluminium Profile Machining Center. After we had meeting with our customers, we decided to make this machine for optimise less setup times and ergonomic usage. This machine has ability to machining aluminium profiles, stainless steel profiles with less money and economical and efficient.

For more safe production, machine is equipped with a cabin. İt has also benefit for reduce noise and keep trashes and swarfs in one place. MAT4800/5 ORCA has a special 3d software for easy programming and also has reading 3d datas as .igs, .stp, .step, .iges, with a special tool magazine, it has ability to have faster tool change. MAT4800/5 ORCA has also MeCloud system which can support Industry 4.0 and Industry 5.0 requirements.

| Depth | 2450 |

| Weight | 5250 |

| Height (with retracted Z-axis without optional roof) | 2500 |

| Total length | 7.100 |

| Max. machining length (5 axis) | Shuttle operation 2400 mm Combined operation 4.800 mm |

| Max. machining length (4 axis) | Shuttle operation 2.750 mm Combined operation 5.500 mm |

| Positioning accuracy | +/- 0.1 mm |

| Direction of machining | 4 (above, behind, front) |

| Disc milling cutter diameter | 120 mm |

| Clamp positioning | autonomus |

| Clamps | 4 standard (+ max. 4 optional) |

| Saw blade diameter | 300 |

| Tool changing | automatic |

| Angle head | optional |

| Routing spindle speed | max. 20,000 rpm |

| Routing spindle power | 9kW, S1 with feedback (air-cooled) |

| Tool holder | ISO-30 |

| Tool tray positions in the automatic magazine | 10 |

| Tool length | max. 150 mm (from extent of taper) |

| Software | MeCAD — MeCAM |

| Compressed air supply | > 7 bar |

| CE power supply (UL optional) | 400 V, 3~, 50 Hz, 35 A |

MeCAM and MeCAD software is a unique software for easy usage. The machine has a 3D CAD software called MeCAD with user friendly interface. The labours can learn and use the machine withing minutes.

Свяжитесь с нами, чтобы получить более подробную информацию о наших продуктах и услугах, а также отправить свои предложения.